Eco-friendly corrosion inhibition for AZ31 magnesium in simulated body fluid

Magnesium implants are promising because they biodegrade, but fast corrosion in physiological environments is still a deployment blocker. I ran an in-vitro screening study in simulated body fluid (37°C) to test biocompatible additives and to explain not just what worked, but why it worked mechanistically.

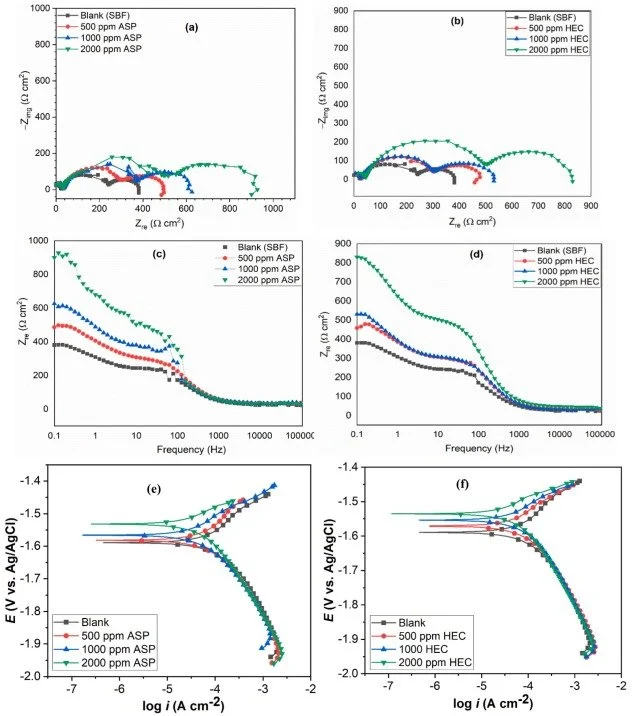

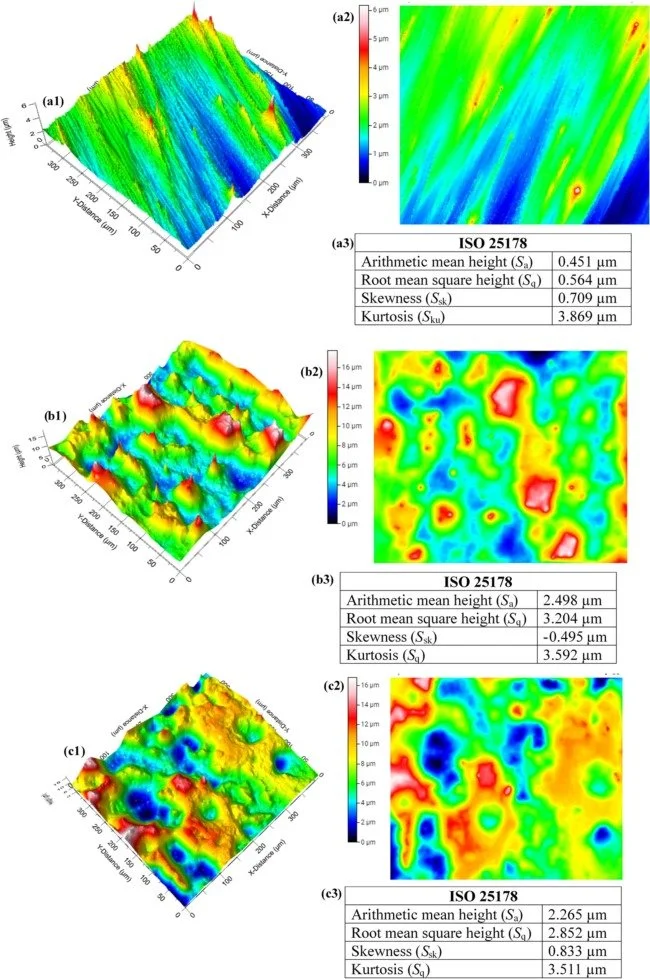

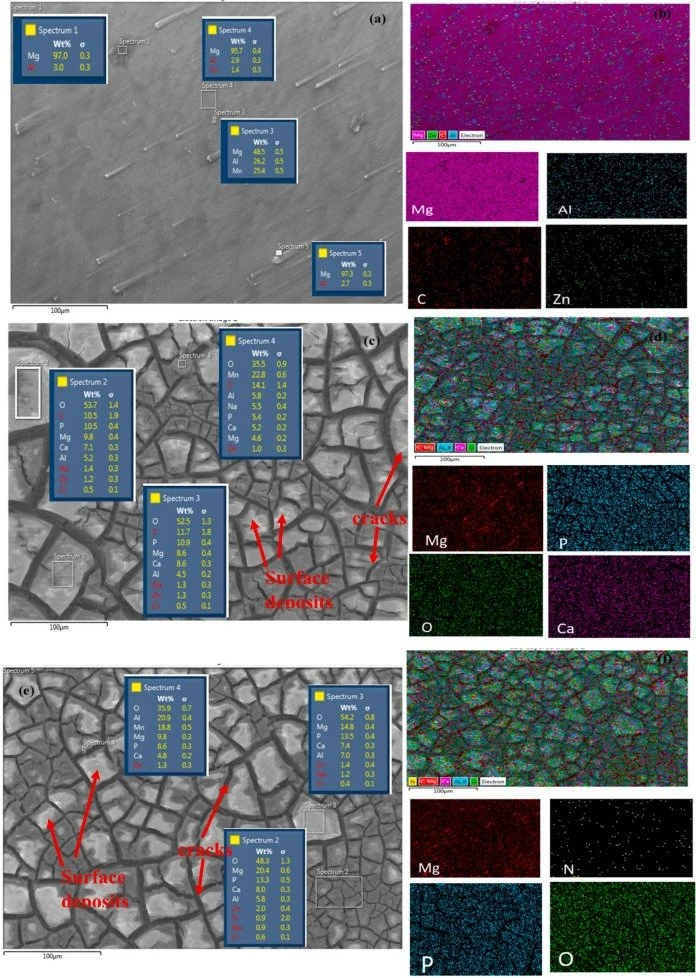

I prepared AZ31 samples, ran the electrochemical testing workflow (including EIS across a wide frequency range and follow-on electrochemical measurements), and validated trends using 48-hour mass-loss. I then tied performance back to surface morphology and chemistry using SEM/EDS, FTIR, and profilometry, and used DRT-based interpretation to separate the dominant corrosion processes.

The strongest result was the ASP + HEC blend: 2000 ppm + 2000 ppm reached 66% protection after 48 hours (mass loss), while ASP and HEC individually reached about 54% and 53% at 2000 ppm. I led most of the experimental pipeline end-to-end (sample prep, experiments, surface characterization, analysis), and wrote most of the literature review and manuscript.

Keywords: EIS, DRT, Mg implants, SEM/EDS, FTIR, profilometry