Tribological characterization of a ceramic–epoxy–Kevlar composite lining

Casing wear in drilling environments drives failures and cost, and simplified lab tests often miss field-relevant behavior. I built and operated a more realistic wear-testing setup to quantify how side load and rotational speed affect wear and to connect measured wear rates to observed surface damage mechanisms.

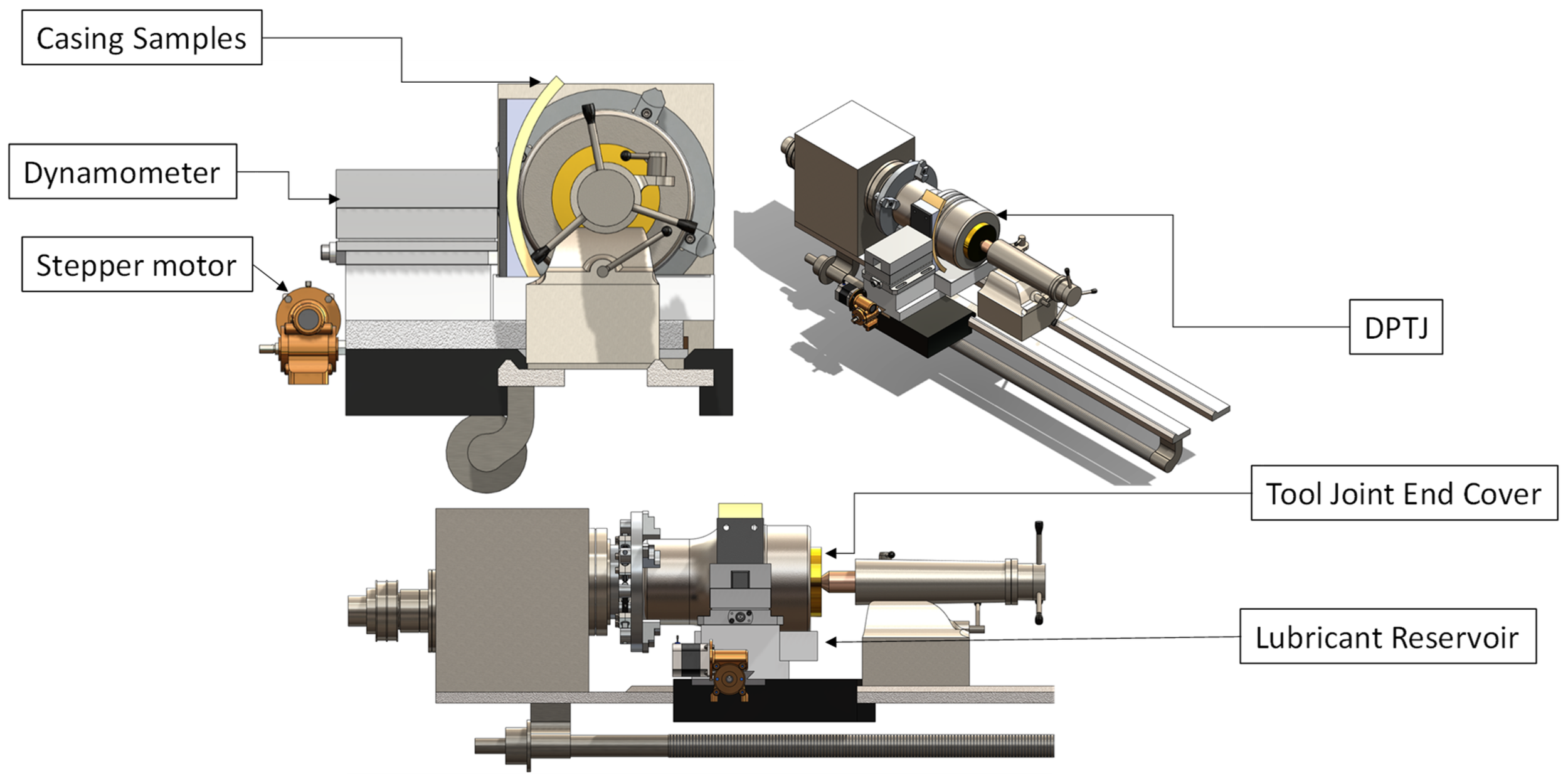

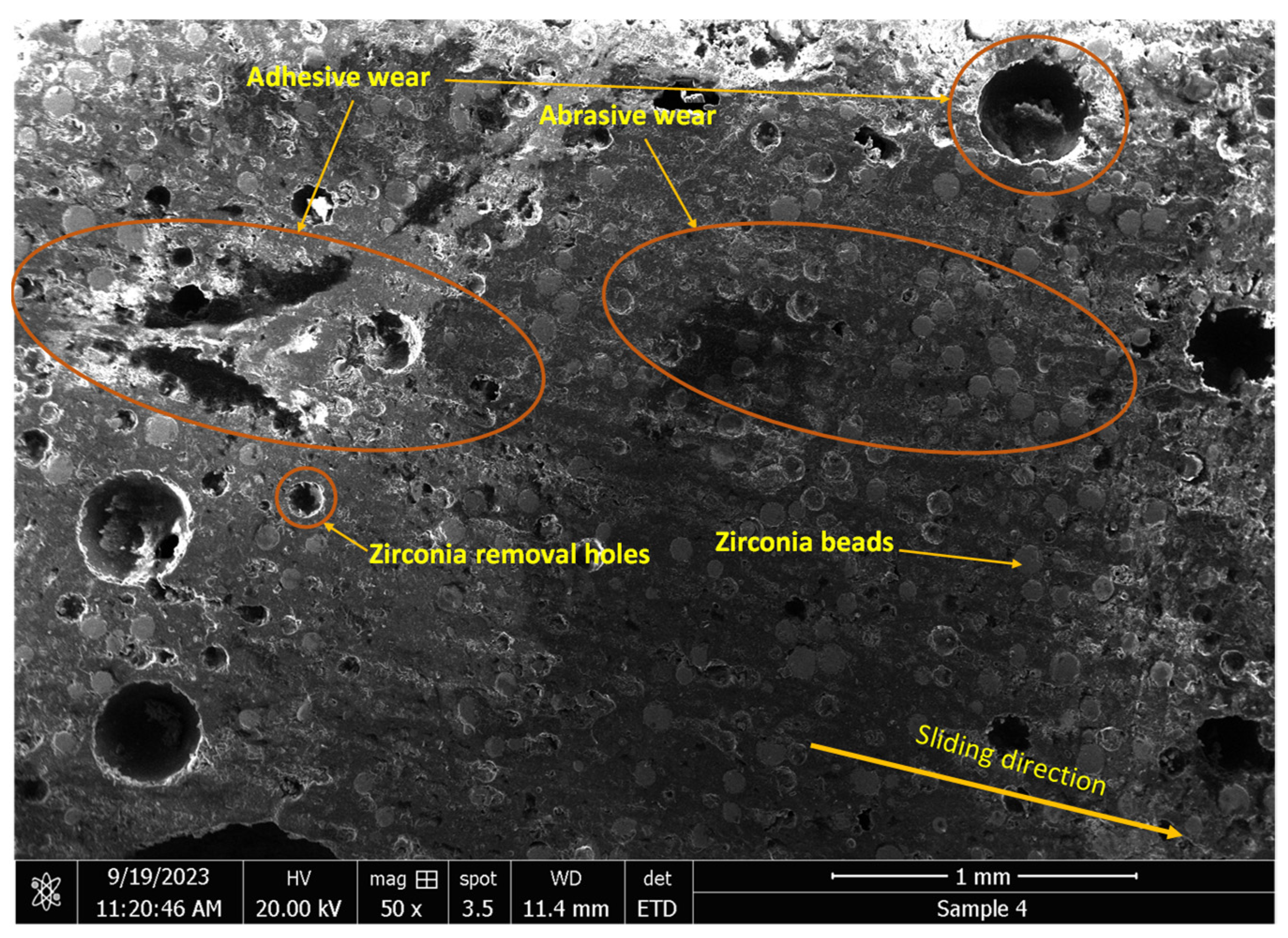

I designed and ran the full instrumented test rig, including closed-loop load control (motor actuation with dynamometer feedback), sensor integration, data logging, and experiment execution across a full matrix of loads and speeds. I then performed surface morphology analysis and interpreted wear mechanisms using microscopy and SEM/EDS, and led the writing and literature review.

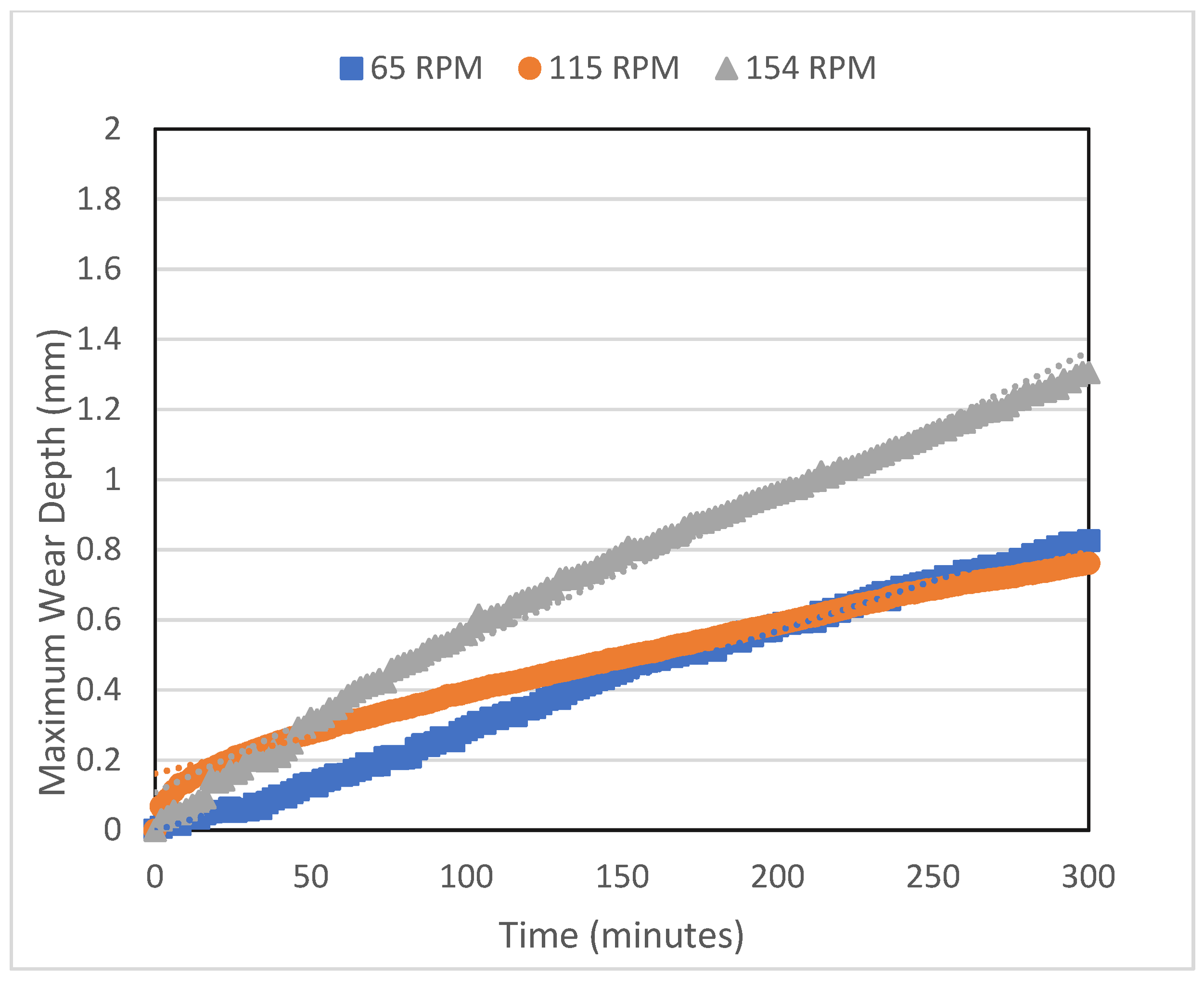

Across tests, the specific wear rate increased strongly with load, and the lowest wear occurred at the intermediate speed (115 rpm), consistent with a lubrication regime shift. Representative K values show the scale of the effect (for example, a sharp increase at 1000 N).

Keywords: tribology, closed-loop control, instrumentation, SEM/EDS